Item NO.:

HR12Order(MOQ):

1PCPayment:

T/T; L/C; WESTERN UNIONProduct Origin:

CHINAColor:

WHITEShipping Port:

SHANGHAI;SHENZHEN;NINGBO;QINGDAO;GUANGZHOULead Time:

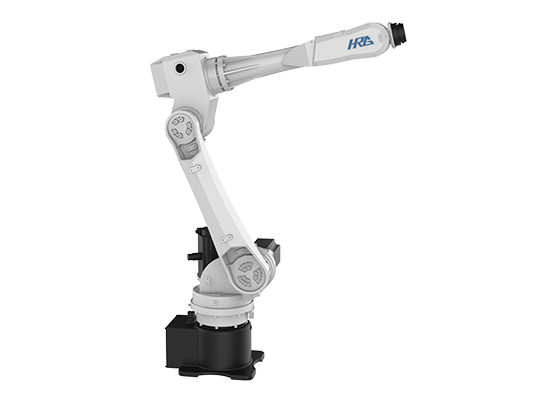

15-30DAYSHR12 12kg Six-axis Industrial Robot

Features

1.The six-axis all-purpose robot of HR series has compact design and is flexible and efficient in operation.

2.Each joint applies high-precision reducers and servo motors to ensure the repetitive positioning accuracy and trajectory accuracy of the robot.

3.The robot has a load of 12kg and a maximum operating radius of 1618mm.

Applications

Load handling,assembly,grinding and polishing, loading and unloading.

Parameters

Model

HR12

Rated load

12kg

Maximum working range

1618mm

DOF

6

Repetitive positioning precision

±0.05mm

Operation temperature

0℃-40℃

Installation method

Ground/support

Typical application

Load handling, assembling, polishing, soldering, loading and unloading, etc.