Item NO.:

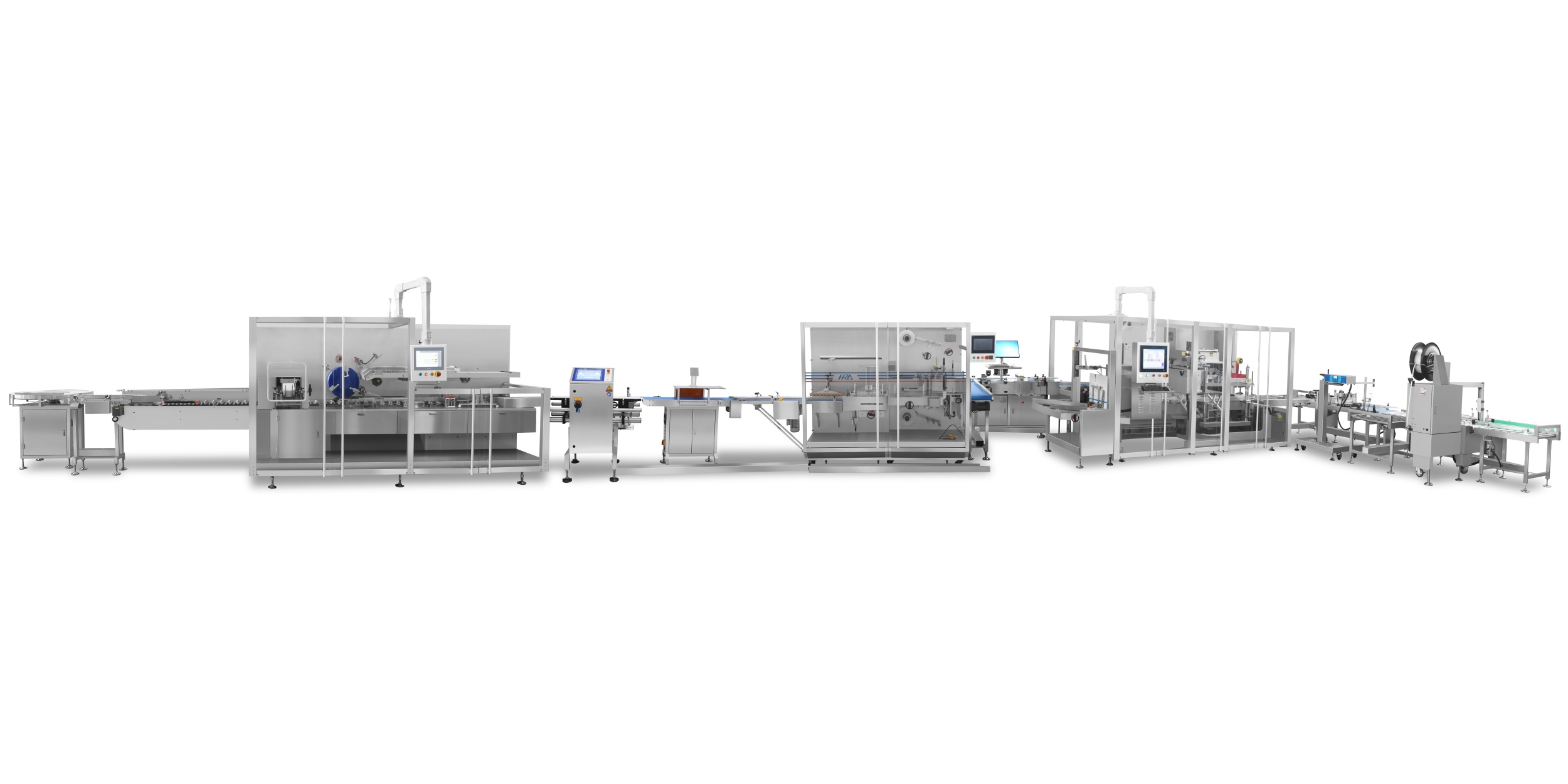

PZXL-300L Bottle Cartoning, Bundling and Case Packing Production LinePayment:

T/T; L/C; WESTERN UNIONProduct Origin:

ChinaColor:

White, SilverShipping Port:

SHANGHAI; SHENZHEN; NINGBO; QINGDAO; GUANGZHOULead Time:

80 DAYSBottle Cartoning, Bundling and Case Packing Production Line

Parameters

|

Model |

PZX-300L |

|

|

Cartoner module |

Carton size(LxWxH) |

Max:210x108x65mm Min:70x33x17mm |

|

Leaflet size(LxW) |

(100-180)x(100-280)mm |

|

|

Leaflet quality |

60-60g/m2 |

|

|

Output |

150-300 cartons/min |

|

|

Power |

2.2KW |

|

|

Banding module |

Bundle size(LxWxH) |

Max:250x180x120mm Min:100x80x60mm |

|

Packaging material |

PE film Width:45-80mm Thickness:60-80um |

|

|

Output |

25-30 bundles/min |

|

|

Power Supply |

220V/50Hz |

|

|

Power |

5KW |

|

|

Compressed Air |

0.6-0.8Mpa |

|

|

Dimensions |

2900x1200x1830mm |

|

|

Weight |

1200KG |

|

|

Case packer |

Case size(LxWxH) |

(300-550)x(200-400)x(200-350)mm (customizable) |

|

Loading speed |

Robot arm≥10 placements/min |

|

|

Power supply |

380V 50Hz |

|

|

Power |

8Kw |

|

|

Compressed Air |

0.6Mpa |

|

|

Dimensions |

4200x2300x1860 |

|

|

Weight |

1200Kg |

|

|

Air pump |

Compressed Air |

0.5-0.8Mpa |

|

Air Flow |

>0.2m2 |

|

|

Power supply |

220V 50Hz; 380v 50Hz |

|

|

Motor Frequency Conversion Capacity |

0-50Hz |

|

|

Dimensions(LxWxH) |

19800X1170X2100 |

|

|

Weight |

8900Kg |

|

|

Total Power |

19.8Kw |

|

|

Certificates |

ISO9001:2000; CE |

|

|

Warranty |

1 year |

|

Features

Cartoner module

1. Easily visible open balcony design, continuous back pushing by 21 groups of pushing shafts, aluminum, stainless steel and tempered glass make the appearance chic and elegant. Intuitive operation and easy maintenance.

2. SEW main motor and synchro-belt main drive ensure high transmission efficiency, low noise, and high level of durability.

3. Wires and pneumatic tubes concealed in stainless steel slots improves the aesthetics inside the machine. Insulated operation area from transmission area avoids cross interventions. Rotation of the control panel from 0 to 100 degrees eases maintenance and cleaning.

4. The width of the carton conveyor belt is adjustable according to the material specifications at the front of the line. The number of layers can be set based on the cartoning specifications. The loading speed is synchronized with the speed of the coming material.

5. Adjusting the width of the material, the width of the carton and the position of the pushing shaft outside the machine mechanism allows wide space and easy access.

6. The carton magazine can be lifted for more convenient commissioning.

7. Picking up cartons by multiple suction heads ensures automatic carton forming and loading. The magazine can store 500-1000 cartons, which are transported by conveyor belt controlled by replenishing pneumatic cylinder.

8. Various checking devices are in place, such as rejecting failed material feeding, missed leaflet, or failed tuck flap locking.

Bundler module

1. State-of-the-art design of structure and electronic control system. Main servo drive insulated from operation area. GMP compliant.

2. Advanced heat-sealing mechanism, perfect non-overlap PE film hot melt sealing, and double film reeling structure save packing materials and reduce cost.

3. Multi-lane pre-stacking mechanism substantially increases the speed of carton grouping and collating whereby the feeding speed can reach 200-400 cartons/minutes in the proceeding stage. Bundling speed is not less than 40 bundles/minute.

4. Bundling strength is adjustable. Changing products and adjusting machine is easy. Format changeover and machine adjustment take less than 10 minutes.

Case Packer module

1.PLC + HMI controls automatic counting, stacking, case erecting, loading and sealing.

2.The stacking system can be adjusted according to the size of the case and stacking pattern.

3. Not less than 10 placements per minute for quick case loading.

4.Case erecting and KDF placing are driven by servo and six-axis Kuka robot set for case loading ensures stable and reliable loading.

5.Highly compatible. Hand-wheel marked with scales for adjustment and fine-tuning.

6.Warnings are in place for machine fault, missed product, missed case or machine jam.