Item NO.:

Two-way Knapsack AGVPayment:

T/T; L/C; WESTERN UNIONProduct Origin:

CHINAColor:

WHITE, GREYShipping Port:

SHANGHAI;SHENZHEN;NINGBO;QINGDAO;GUANGZHOULead Time:

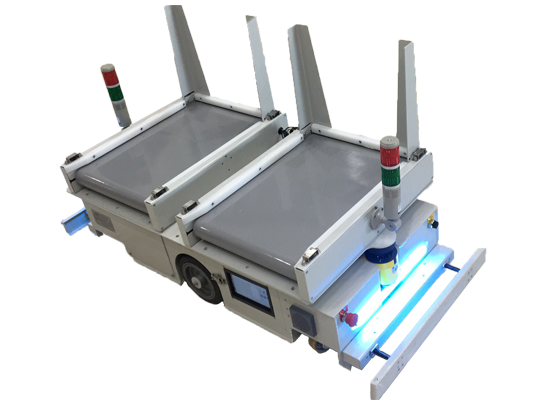

15-30DAYSTwo-way Knapsack AGV

Features

Two-way Knapsack AGV directly docks the machine for feeding and conveying materials through AGV system. It helps to realize unmanned warehousing and equipment processing and is an ideal alternative to manual and hand-operated logistics vehicles.

Parameters

Dimensions

1398x660x450mm

Navigation mode

Single laser navigation+bidirectional magnetic stripe navigation

Load capacity

Within 200kg

Positional accuracy

Laser positioning±30mm, magnetic stripe positioning±10mm

Bearing mode

Roller knapsack, double-position

Climbing ability

≤3°

Drive mode/voltage

Two-wheel differential speed drive/48V

Safety protection

Lidar, laser obstacle avoidance sensor, mechanical safety touch, emergency stop button

Direction of travel

Move back and forth, turn right and left, rotate in the original place

Alarm type

Visual and audible alarm

Driving speed

Straight line 0-60m/min

Battery type

48V 80Ah lithium battery

Control mode

Industrial control computer, PLC

Charge mode

Automatic charging, manual charging

Communication

Wireless LAN, wireless communication

Manual remote control

Provided